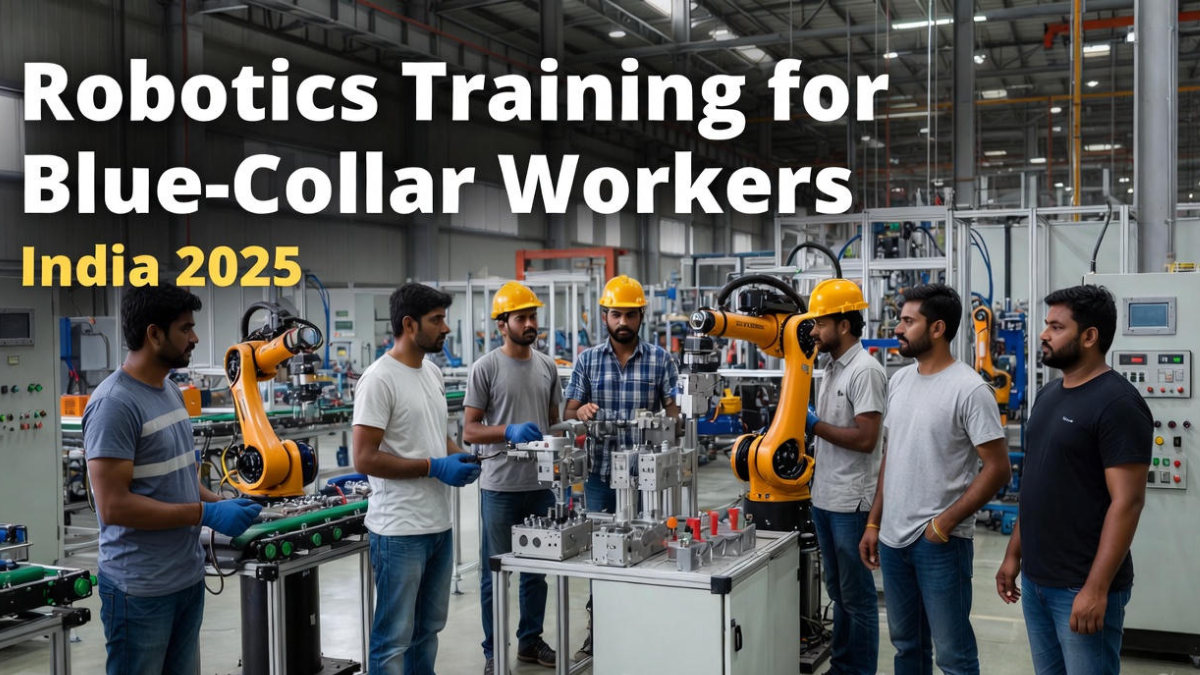

The rise of Robotics Training India 2025 marks a transformative shift in how India’s workforce adapts to automation and industrial modernization. As factories, manufacturing plants, and logistics sectors introduce more robots into daily operations, blue-collar workers must upgrade their abilities to stay relevant. This is where structured training programs come in, offering hands-on sessions in operating, maintaining, and troubleshooting robotic equipment. With the support of national initiatives and corporate partnerships, Skill development programs focused on robotics are becoming widely accessible. As a result, Robotics Training India 2025 is preparing India’s workforce for a future where humans and robots work side by side.

Why Skill Development in Robotics Is Becoming Essential

Automation is expanding across almost every industry, making Skill development a top priority for both employers and employees. Traditional labor roles are evolving, requiring workers to understand robotics, sensors, and automated workflows. The core aim of Robotics Training India 2025 is not to replace workers but to empower them with the knowledge they need to work confidently with advanced machines. These training programs reduce job insecurity, increase productivity, and open doors to higher-paying roles. As robotics becomes integral to assembly lines, warehouse sorting, packaging, and material handling, skill development ensures workers stay competitive and future-ready.

How Robotics Training India 2025 Programs Work

Training programs under Robotics Training India 2025 follow a structured curriculum that blends theory with practical experience. Trainees learn robot programming basics, safety protocols, maintenance routines, and the functionality of sensors and actuators. With support from Skill development initiatives, many institutions offer real-world simulation labs where workers can practice controlling robotic arms, automated conveyors, and collaborative robots (cobots). Modules also include troubleshooting and emergency handling, ensuring workers can respond quickly if issues arise. These programs are often conducted in partnership with government skill missions, tech companies, industrial training institutes (ITIs), and vocational centers.

Comparison: Traditional Industrial Work vs Robotics-Enabled Work

| Feature | Traditional Blue-Collar Work | Robotics Training India 2025 |

|---|---|---|

| Skill development Need | Low to moderate | High and essential |

| Job Complexity | Manual, repetitive | Tech-enabled and skilled |

| Safety Levels | Moderate | Increased safety with robotics |

| Job Growth | Limited | Higher due to automation demand |

| Learning Curve | Basic | Advanced technical training |

| Long-Term Career Stability | Medium | Very strong post training |

This comparison clearly shows how Robotics Training India 2025 improves career stability and growth. With structured Skill development, blue-collar workers become better equipped to handle modern industry demands.

Benefits for Workers and Industries

The advantages of Robotics Training India 2025 extend to both employees and employers. Workers gain confidence, technical expertise, and access to higher-paying roles. Industries benefit from improved productivity, fewer operational errors, and enhanced workplace safety. With the support of Skill development programs, companies can reduce downtime caused by machine issues because trained workers handle maintenance more efficiently. Robotics-literate employees also help companies adopt new technologies faster, increasing competitiveness in global markets. As more training programs emerge, India’s workforce becomes stronger, more adaptable, and ready for advanced manufacturing.

Challenges and the Road Ahead

Despite rapid progress, Robotics Training India 2025 faces challenges. Many workers may feel intimidated by technology or fear job replacement. Awareness about Skill development programs in rural and semi-urban areas is still limited. Additionally, training institutions need more modern equipment and experienced instructors. However, governments and industries are investing heavily in robotics labs, online learning platforms, and mobile training units. With continuous support, India’s blue-collar workforce will gradually overcome hesitation and embrace automation. Improved access to training will ensure that every worker has the opportunity to learn, grow, and succeed in the new industrial landscape.

Conclusion

The evolution of Robotics Training India 2025 reflects India’s commitment to preparing its workforce for an automated future. Through accessible Skill development programs, blue-collar workers can master modern robotics and secure long-term careers in industries undergoing rapid transformation. With hands-on training, improved safety, and better job opportunities, robotics training is strengthening the backbone of India’s economy. As automation accelerates, skilled workers will play a crucial role in shaping the future of manufacturing, logistics, and industrial growth.

FAQs

What skills do workers learn through Robotics Training India 2025?

Workers learn robot handling, programming basics, safety protocols, and maintenance techniques as part of Skill development programs.

Is robotics training difficult for beginners?

No, programs are designed for all skill levels, and Skill development modules gradually build knowledge.

Will robotics reduce job opportunities in India?

No, Robotics Training India 2025 helps workers upgrade their skills, leading to better job stability and new opportunities.

Who can enroll in robotics training programs?

Any blue-collar worker interested in upskilling can join, regardless of prior technical experience.

Click here to know more.